SCP Contact

Siam Casting Powders Ltd.

SIAM CASTING POWDERS LTD.

SIAM CASTING POWDERS

SUPPLIES THE FINEST-QUALITY

INVESTMENT POWDERS AND

MATERIALS FOR THE LOCAL

CASTING INDUSTRIES

SCP - TECHNICAL DATA

Jewellery Trouble Shooting Casting problems

Flashing or Finning

Cause : Incorrect powder/water ratio (too much water)

REMEDY :

Use correct amount of water (especially important with vacuum investing machines)

Cause : Work time of investment too long. Slurry start to set while still under vacuum.

REMEDY :

Ensure the work time is fully used.

Normally 8 minutes.

Cause : Casting the material with too much force.

REMEDY :

For centrifugal casting, use the correct

spin For vacuum casting, reduce pressure.

Cause : Moving flask too soon

REMEDY :

Leave the flasks for at least 1 hour.

Cause : Moulds allowed to dry out before burn out.

REMEDY :

If not burning out the same day, keep moulds wet by covering with wet sacking.

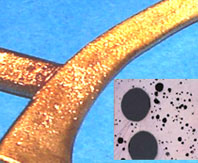

Bubbles

Cause : Investment too thick. Too little water.

REMEDY :

Use correct powder/water ratio.

Cause : Vacuum pump/tank faulty.

REMEDY :

Ensure equipment is regularly serviced

and adequate for the task.

Water marking

Cause : Incorrect powder/water ratio (too much water)

REMEDY :

Use correct amount of water (especially important with vacuum investing machines)

Cause : Work time of investment not used up.

REMEDY :

Ensure the work time is used up and slurry temperature is 20 – 30 °C.

Cause : Investment powder expired(too old)

REMEDY :

Do not keep investment too long time.

Blister

Cause : Dewax soak time not long enough.

REMEDY :

Extend time for dry dewax at least 3 hours

(temperatures between 150 to 250°C)

Cause : Flasks dewaxed at too high temperature.

REMEDY :

Do not exceed 250°C during dry de-wax.

Wax will boil and erode investment surface.

Cause : Flasks put in furnace too soon after investing.

REMEDY :

Leave flasks undisturbed for a minimum of one hour before de-wax.

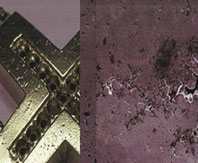

Rough surfaces

Cause : Rough waxes.

REMEDY :

Use too much powder on the rubbers.

Cause : Flasks dewaxed at too high temperature..

REMEDY :

Do not exceed 250°C during dry de-wax.

Wax will boil and erode investment surface.

Cause : Steam de-wax for too long..

REMEDY :

Steam, de-wax for a maximum of 1 hour.

Steam will erode surface of the casting.

Cause : Flasks overheated during burn out..

REMEDY :

Ensure maximum burn out temperature

does not exceed 750 °C

Cause : Metal temperature too hot.

REMEDY :

Reduce metal casting temperature.

Rough surfaces

Cause : Usage of low quality metal.

REMEDY :

Do not use more than 50% recycled alloy

and ensure it is clean.

Cause : Reaction with investment temperature. (Flask temperature too hot)

REMEDY :

Reduce flask temperature down, Specially

on big design.

Cause : Overheating the metal.

REMEDY :

Reduce metal casting temperature.

Cause : Temperature inside furnaces over.

REMEDY :

Ensure the quality of Thermocouple can control temperature.

Shrinkage porosity

Cause : Incorrect spruing

REMEDY :

Sprues should be attached to the heaviestpiece of the casting.

Thereshould be sufficient sprues to ensure the casting is adequately fed.

Cause : Flask temperature too cold.

REMEDY :

The flask temperature should be just hot enough to achieve complete fill.

Incomplete casting

Cause : Metal or flask temperature too cold.

REMEDY :

Increase casting temperatures. If the

metal or flask is too cold, the metal will

freeze before completely filling the mould.

Cause : Improperly sprued.

REMEDY :

the sprue system should be designed

to allow the metal to enter easily and

without restriction.