SIAM CASTING POWDERS LTD.

If you like to hear a voice at the other end, we're there for you with everything you need.

Inquiry Form

We will get in touch with you shortly

SCP - Products

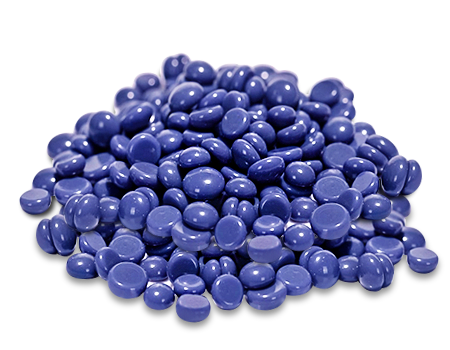

SCP Silicone Rubber

Low Temperature

Flu Green

– Very Low Shrinkage

– High Dimension Accuracy

– High Level Surface Finish

– Detailed Reproduction of Patterns

– High Tear Strength

– No Release Agents Required

SCP silicone rubber are packed in 5kg. boxes and 2kg. boxes.

5.kg.box : 500g. / sheet

2 kg.box : 250g. / sheet

Product Detail

Flu Green

SCP Silicone Rubber Low Temperature

SCP silicone rubber / Low Temperature

– High Hardness silicone rubber produce strong mold.

– Good Tear and Tensile Strength.

– Flu. Green produce waxes with a low shrinkage and smooth high shine finish that won’t stick to the mold. Smooth shiny waxes means faster cleaning and less polishing of finished castings.

– Excellent return to shape, or “memory”.

– High thermal conductivity means that waxes cool more quickly, increasing the number of wax patterns that can be made per hour.

Properties

| Properties | Values |

| Vulcanisation Temperature | 90-100°C 194-212°F |

| Vulcanisation Time | 15 mins / 10 mm of mould thickness |

| Shore Hardness | 50+-2 |

| Tear Strength | 27.1 N/mm |

| Tensile Strength | 8.8 N/mm2 |

| Elongation | 659% |

Instruction

Pack base of mould with required grade of rubber.

Insert pattern, having inserted core of different grade rubber if required.

Pack top of mould with required grade of rubber.

LTV vulcanise for 15 minutes per 6mm of mould thickness at 80 °C QCV vulcanise for 5 minutes per 6mm of mould thickness at 90 °C

LTV vulcanise for 15 minutes per 6mm of mould thickness at 80 °C

Cut mould.

Mould is ready to use.