SIAM CASTING POWDERS LTD.

SIAM CASTING POWDERS

SUPPLIES THE FINEST-QUALITY

INVESTMENT POWDERS AND

MATERIALS FOR THE LOCAL

CASTING INDUSTRIES

SCP - Products

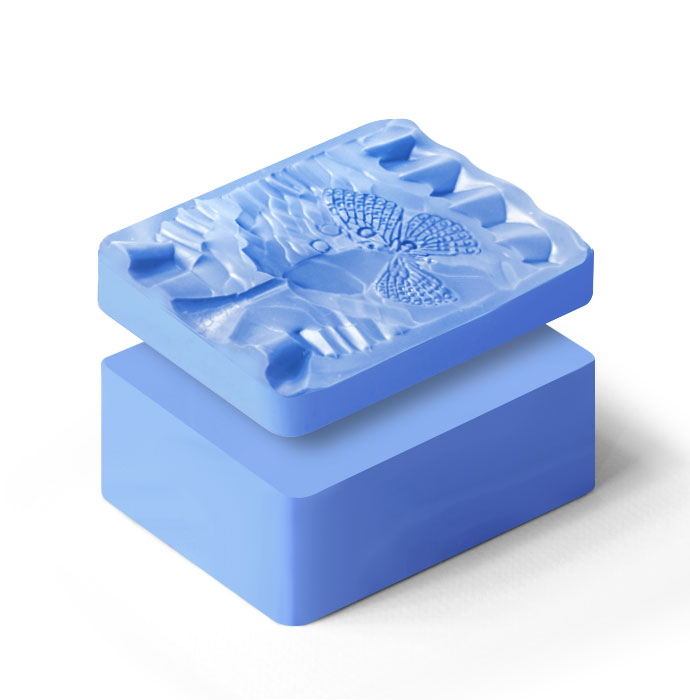

SCP Silicone Rubber

Low Temperature

38 L Light Blue

Soft silicone rubber

for general purpose

and high flexibility.

Excellent tear and

tensile Strength.

Can be used in

combination with

other same low temp.

rubber as insert.

Excellent return

to shape, or “memory

SCP silicone rubber are packed in 5kg.

boxes and 2kg. boxes.

5.kg.box : 500g. / sheet

2 kg.box : 250g. / sheet

Product Detail

38 L Light Blue

SCP Silicone Rubber

Low Temperature

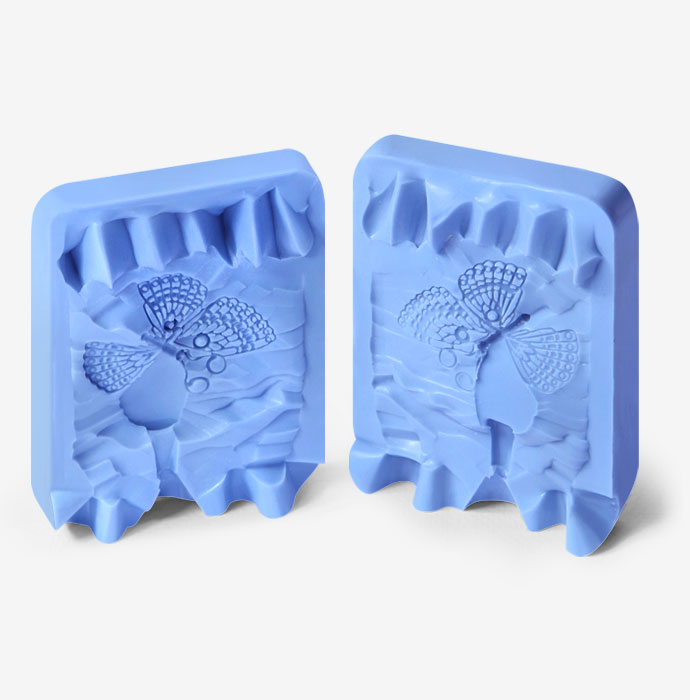

• Long Life Moulds

• High Dimension Accuracy

• High Level Surface Finish

• Detailed Reproduction of Patterns

• High Tear Strength

• No Release Agents Required

Properties

| Properties | Values |

| Hardness (Shore A) | 38±2 |

| Shrinkage | <1 % |

| Tear Strength | > 22 N/mm |

| Tensile Strength | > 7 N/mm2 |

| Elongation (%) | > 700% |

| Vulcanisation temperature | 90 ํc. – 100 ํc. |