|

|

Gem Set

Gem Set has been specially formulated to protect precious stones such as diamonds, when they are set into the wax patterns, burned out and cast , to ensure no damage to the stones during the burn out cycle.

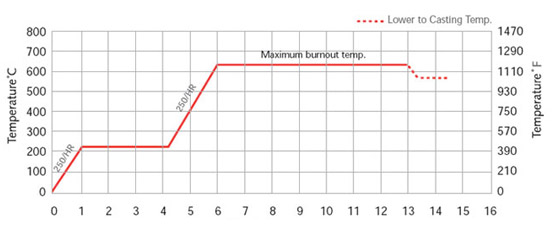

Gem Set has been specially formulated to protect precious stones such as diamonds, when they are set into the wax patterns, burned out and cast , to ensure no damage to the stones during the burn out cycle. The maximum temperature achieved during the burnout cycle MUST not exceed 630°C.

Gem Set holds the stones in place during the dewax period, and protects them from the heat during the remainder of the burnout process, andthe molten metal when cast. Gem Set will producehigh definition, clean surface castings, with stones that remain as clear as they were before burnout.

Extensive permeability testing and development has taken place to ensure maximum carbon is released from the mould during burnout. It is formulated with the special additives to enhance stone-in-place casting results and improve cleanoff. Gem Set will cast all alloys melting below 1250°C.

| WATER TO POWDER RATIO | |

| MACHINE VACUUM MIXING | 38 : 100 |

| HAND MIX THEN VACUUM | 38 : 100 |

|

• DO NOT STEAM DE-WAX • Do not burnout above 630 ํC • Do not quench, only knock out when cold |

|

| MACHINE VACUUM MIXING | Min |

| Weigh out water & powder | 0 |

| Add powder to water | |

| Mix under vacuum | 1 |

| Stop mixer and scrape blades | 0.5 |

| Mix under vacuum | 3.5 |

| Pour flasks | 2 |

| Vacuum flasks | 1 |

| Total time taken | 8 |

| HAND MIX THEN VACUUM | Min |

| Weigh out water & powder | 0 |

| Add powder to water | |

| Mix by hand | 1 |

| Mix with machine | 3 |

| Vacuum mixer bowl | 1 |

| Pour flasks | 1 |

| Vacuum flasks | 2 |

| Total time taken | 8 |

| Remove tape from flasks after | 90 |

Do not remove flasks from furnace to cast until they have been held at casting temperature for a minimum of 1 hour. lf held for less than 1 hour, the core of the flasks will be at a much higher temperature than the digital temperature display states, and may result in metal mould reaction.